Product Description:

One of the main advantages of the Lebus Sleeve product is its material composition. Made from high-quality steel, these rope sleeves are highly portable and easy to install. Their non-magnetic and insulated properties make them an ideal choice for use in a wide range of industries, including construction, mining, and marine applications. Additionally, they are anti-static, which minimizes the risk of electrical shock and damage to sensitive equipment.

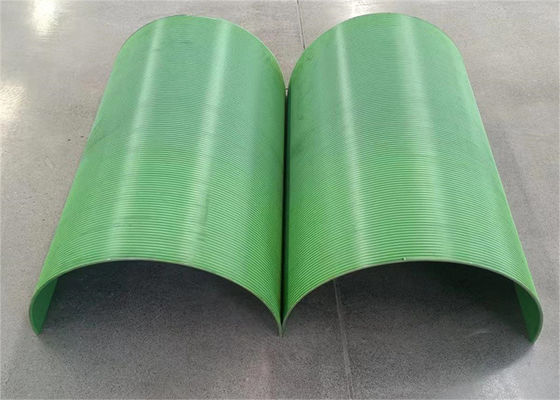

Another key feature of the Lebus Sleeve product is its Lebus grooved, While ensuring the regular winding of the wire rope,thesesleeves provide maximum protection against abrasion and other forms of damage. They are also easy to install, with no special tools or equipment required.

Whether you are looking for split sleeves to protect your ropes from wear and tear or to extend their service life, the Lebus Sleeve product is an excellent choice. With its superior design and high-quality materials, it offers unmatched protection and durability for ropes of all sizes and types.

Applications:

The LBSS-Series Lebus Sleeve product is a two-half split type rope spooling system. It is designed to be heat resistant and can withstand harsh environments. The product is made in Shijiazhuang, Hebei, China, and has certifications such as CCS, ABS, and ISO9001.

The LBSS-Series Lebus Sleeve product is perfect for industries such as oil and gas mining, offshore, construction, scientific research, and rescue. It is used for regular winding of wire rope and is ideal for scenarios where rope spooling systems are needed.

The LBSS-Series Lebus Sleeve product comes with a smooth winch drum accessory equipment that adds to its efficiency and effectiveness. It is available for purchase at a negotiable price with a minimum order quantity of 1 pcs. The product is packaged in an export standard wooden case or pallet and has a delivery time of 15-30 days.

The LBSS-Series Lebus Sleeve product is easy to use and highly durable. Its supply ability is 1000 sets, making it readily available for customers. Its application occasions include rescue operations, scientific research expeditions, and construction sites. The product can withstand harsh environments and is perfect for offshore operations.

Customization:

- Brand Name: LBS

- Model Number: LBSS-Series

- Place of Origin: Shijiazhuang, Hebei, China

- Certification: CCS, ABS, ISO9001

- Minimum Order Quantity: 1 Pcs

- Price: Negotiation

- Packaging Details: Export Standard Wooden Case Or Pallet

- Delivery Time: 15-30 days

- Payment Terms: T/T, L/C, Etc

- Supply Ability: 1000 Sets

- MOQ: 1

- Groove bottom thickness: 6mm-50mm

- Warranty: 12 Months

- Material: Polymer Nylon, Etc

- Design: Lebus Grooves

Our customizable steel sleeves, two-half split sleeves, and rope spooling system are perfect for any application. Contact us today to discuss your specific needs and to receive a quote.

Support and Services:

Our technical support and services for the Lebus Sleeve product include:

- Expert guidance on product selection, installation, and maintenance

- Detailed product information, including specifications and performance data

- On-site support and troubleshooting

- Training and education for customers and their employees on the proper use and care of the product

- Repair and replacement services for damaged or worn parts

Packing and Shipping:

Product Packaging:

The Lebus Sleeve product is carefully packaged to ensure safe delivery to our customers. Each sleeve is individually wrapped in a protective layer to prevent any scratches or damage during transportation. The sleeves are then placed in a sturdy cardboard box with additional cushioning materials to further protect them from any potential damage.

Shipping:

We offer fast and reliable shipping options to get your Lebus Sleeves to you as quickly as possible. Our shipping partners use trusted delivery services to ensure that your order arrives on time and in perfect condition. We also provide tracking information so you can keep an eye on your order every step of the way.

FAQ:

Here are 5 frequently asked questions and answers about the LBS LBSS-Series Sleeve:

Q: What is the LBSS-Series Sleeve?

A: The LBSS-Series Sleeve is a type of wire rope socket designed to provide a secure and reliable termination point for wire ropes.

Q: Where is the LBSS-Series Sleeve made?

A: The LBSS-Series Sleeve is made in Shijiazhuang, Hebei, China.

Q: What certifications does the LBSS-Series Sleeve have?

A: The LBSS-Series Sleeve is certified by CCS, ABS, and ISO9001.

Q: What is the minimum order quantity for the LBSS-Series Sleeve?

A: The minimum order quantity for the LBSS-Series Sleeve is 1 piece.

Q: What are the payment terms for the LBSS-Series Sleeve?

A: The payment terms for the LBSS-Series Sleeve are T/T, L/C, etc. Prices are negotiable.

Q: What is the delivery time for the LBSS-Series Sleeve?

A: The delivery time for the LBSS-Series Sleeve is typically 15-30 days.

Q: What is the packaging for the LBSS-Series Sleeve?

A: The LBSS-Series Sleeve is packaged in export standard wooden cases or pallets.

Q: What is the supply ability for the LBSS-Series Sleeve?

A: The supply ability for the LBSS-Series Sleeve is 1000 sets.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!