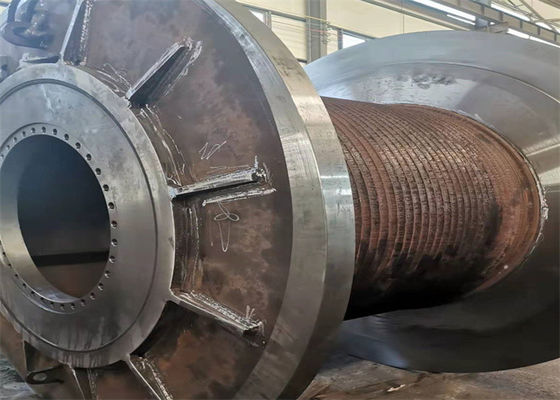

Heavey Duty Tower Crane Parts 40mm Wire Rope LBS Grooved Winch Drum

Grooved Winch Drum

Material: Carbon Steel, Alloy Steel, Stainless Steel, Aluminum, High-Strength Steel, Etc

Material Standards: GB, AISI, ASME, ASTM, JIS, DIN, ...

Ambient Temperature: -40 ° C To +45 ° C

Stroage Ambient Temperature: -40 ° C To +50 ° C

Groove Type of Drum: Spiral Grooves or Lebus Grooves

The Rotation Direction of The Drum: Lefthand or Righthand

Processing method: Machine Work

Wire Rope Diameter: 3 MM~100 MM

Processing Equipment: CNC machining center

Processing type :

Lebus grooved drum

The groove is cut directly into the body of the drum.(according to customer‘s requirements.

The flanges are either welded or screw-bolted.)

Split-lebus grooved sleeves (shell )

The whole lebus grooved drum is divided into the upper and lower parts,which we call them lebus split-sleeves. The sleeves are available a smooth drum or helical drums.

LBSD Series Grooved drum :

About Size:

We can manufacture all sizes of drums. From now, we have finished the drums from 50mm to 2000mm in diameter. And its length range is from

100mm to 2000mm.

Some parameters:

| Rope diameter(mm) |

5 12 24 32 42 58 |

| Grooved drum diameter(mm) |

80 150 300 500 800 1100 |

| Width between the flanges flanges(mm) |

150 280 300 460 750 1000 |

| Rotation direction |

L R R L L R |

| Number of layers |

3 2 4 6 8 8 |

| Rope capacity(m) |

18 19 43 127 360 1800 |

Our equipment

Our factory has more than 2000 sets of advanced equipment such as casting, forging, gear processing, sheet metal stamping, riveting, heat treatment and mechanical processing. In recent years, the Germany CW1000 machining center, CNC four axis, five axis linkage machining center, CNC punch, large CNC hobbing gear grinding machine, large CNC floor boring and milling machine, Vacuum electron beam welding, CNC welding robot and 80 roll machine and other advanced processing equipment.

Why choose us

With the reliability of the product, it has achieved remarkable results in military and civil applications.

For example, it has been used in Marine vessels, oil drilling, construction machinery, coal metallurgy and other fields

In addition, the products are also exported to the United States, Britain, Spain, Germany, France, Italy, Denmark and other European and American countries, as well as Japan, South Korea, Singapore, Australia and other Asia-pacific countries

In the process of production and operation, we adhering to the "pursuit of excellence, excellence" concept and deep cooperation with domestic and foreign universities, research institutes, formed a "production, use, collaborative innovation" model of development, rigorous scientific method and the specialization of production, the combination of constantly absorbing new technology improved product of research and development, producing a batch of and a batch of high quality products suitable for the market,Also for customers to solve one after another technical problems.

At the same time, the company has always followed the service attitude of "keep promise, treat each other honestly", looking forward to sincere cooperation with customers at home and abroad!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!