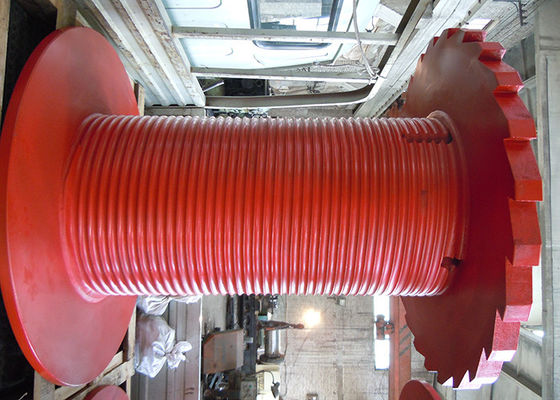

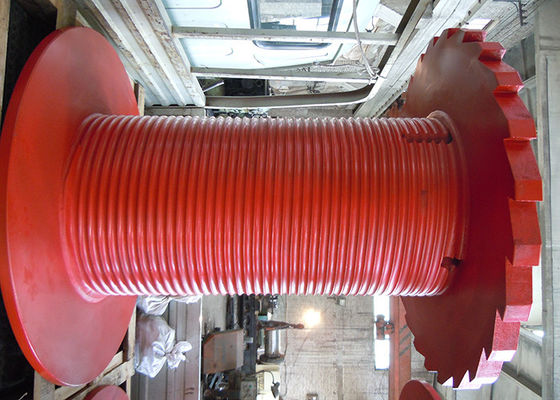

Mining Equipment Wrie Rope Special Design Lebus Grooved Winch Drum

mining hoist

A mechanical device used to pull a load by means of a wire rope wound around a drum. It is mainly used for pulling vehicles underground or on the ground, removing the pillar of coal mining face and other auxiliary transportation work.

The role of mining winch

Mechanical equipment used for pulling load moving with wire rope wound on the drum, mainly used for underground or ground traction vehicles in mines, removing pillars of coal face and other transportation work.

Classification of mining winches

According to the power is divided into electric, pneumatic and hydraulic 3. According to the way of force transmission between wire rope and drum, there are two kinds of winding and friction wheel; According to the use of dispatching winch, return column winch, endless rope winch and transport winch 4.

Precautions for winch operation

The driver should pay attention to the operating conditions and the wear of the wire rope at any time. When the load changes and improves, the driver should stop 0.5m above the ground and continue to rise when there is no problem. The driver shall not leave his post until the suspended object falls completely to the ground. When resting or suspending operations, objects or cages must be lowered to the ground. After work, should cut off the power supply, close the switch box

Service conditions of Lebus groove

1. The flanges of drum shall be perpendicular to drum wall at any conditions,even under the load.

2. The rope must be kept under tension in the process of spooling so that the rope will be crushed against groove wall. When spooling can not meet this condition,a press roller shall be used.It is generally recommended that the tension of the rope should be at least 2% breaking tension or 10% working load.

3. The fleet angle range should generally never be more than 1.5 degrees and not less than 0.25 degrees.

4. When the wire rope released from the drum goes around the sheave,the center of sheave should be over the center of drum.

5. The rope must be kept round,not loose,even under the maximum load.

6. The rope must be anti-rotation structure.

Pls measure the change of rope diameter under different load

1. Offshore Marine machinery: Offshore petroleum crane winch, Mooring winch, Traction winch, Man-riding winch, Anchor winch, Hydrologic winch

2. Engineering machinery: Cable winch, Tower crane, Piling machine, Hydraulic winch

3. Oil field industry: Oil drilling rig, Petroleum tractor hoist, Petroleum workover rig, Trailermounted pumping unit winch , Logging winch, etc

4. The building machinery: Building wipe wall winch, Winding hoist, Windlass

5. Mining winch: Dispatching winch, Prop-pulling winch,Sinking winch, etc

6. Crane machinery: The bridge lifting machine, Tower crane, Gantry crane,Crawler crane winch

Technical Parameters

| No: |

Wire diameter(mm) |

Pulling Force(KN) |

Rotation Direction |

Drum Diameter(mm) |

Drum Length(mm) |

| 1 |

3~8 |

3~10 |

Lefthand,Righthand |

>160 |

<1000 |

| 2 |

10~16 |

12~20 |

Lefthand,Righthand |

>320 |

<1000 |

| 3 |

18~24 |

20~80 |

Lefthand,Righthand |

>480 |

<1000 |

| 4 |

26~32 |

100~120 |

Lefthand,Righthand |

>640 |

<1000 |

| 5 |

34~40 |

150~200 |

Lefthand,Righthand |

>800 |

<1000 |

| 6 |

42~50 |

240~400 |

Lefthand,Righthand |

>1000 |

<1000

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!